Views: 0 Author: Site Editor Publish Time: 2025-11-04 Origin: Site

Imagine a world where food stays fresh longer and flavors are enhanced naturally. Sodium diacetate makes this possible. This versatile compound plays a crucial role in food preservation and flavor enhancement. In this post, you'll learn how sodium diacetate is made, its industrial importance, and its diverse applications across various sectors.

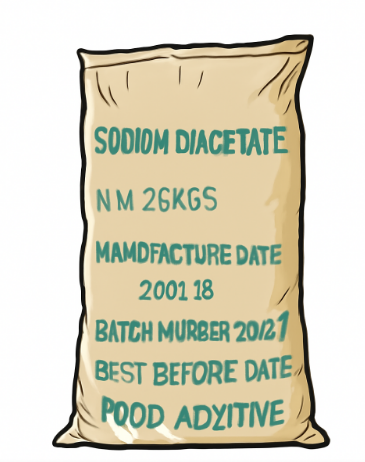

Sodium diacetate is a chemical compound formed by combining sodium acetate and acetic acid. Its formula is often represented as CH₃COONa·CH₃COOH, showing it as a molecular complex rather than a simple salt. This unique structure results from an acid-base interaction where sodium acetate, a weak base, pairs with acetic acid, a weak acid. The compound appears as a white crystalline powder and has a mild vinegar-like smell due to the acetic acid component.

The molecular complex is stable and contains roughly equal parts of sodium acetate and acetic acid. This balance gives sodium diacetate its characteristic properties, such as antimicrobial activity and acidity regulation. The compound’s molecular weight (anhydrous) is approximately 142.09 g/mol.

Sodium diacetate plays a vital role in the food industry, mainly as a preservative and flavor enhancer. It helps extend the shelf life of various food products by inhibiting the growth of bacteria, molds, and yeast. Its antimicrobial action is attributed to the acetic acid portion, which penetrates microbial cell walls and disrupts their metabolism.

Here are some common food applications:

Preservative in Meat Products: It prevents spoilage and rancidity in processed meats like sausages and deli meats.

Baked Goods: It helps maintain freshness and inhibits mold growth in bread, cakes, and pastries.

Snack Foods: Used in products like chips and crackers to enhance flavor and prevent microbial contamination.

Beverages: Acts as an acidity regulator, improving flavor stability in soft drinks and juices.

Sodium diacetate is recognized as safe by regulatory agencies such as the U.S. FDA and is listed under Generally Recognized As Safe (GRAS) substances. Its breakdown products are water, sodium ions, and carbon dioxide, which pose no harm to human health or the environment.

One common way to make sodium diacetate is by neutralizing acetic acid with sodium carbonate. The reaction involves mixing acetic acid and sodium carbonate, which produces sodium acetate, water, and carbon dioxide gas. To form sodium diacetate, an extra amount of acetic acid is added to the sodium acetate. This results in a balanced mix of sodium acetate and acetic acid, creating sodium diacetate.

This method is popular because sodium carbonate is affordable and readily available. However, the carbon dioxide gas produced must be carefully managed to avoid disrupting the reaction or crystallization steps. Controlling the reaction temperature around 40-50°C helps maintain efficiency and product quality.

Another way is neutralizing acetic acid with sodium hydroxide. This reaction produces sodium acetate and water without releasing carbon dioxide, making it cleaner than the sodium carbonate method. After forming sodium acetate, acetic acid is added in a 1:1 molar ratio to produce sodium diacetate.

This method requires precise control of reactant ratios to ensure the right balance between sodium acetate and acetic acid. It’s often preferred in industrial settings where product purity is critical. The reaction is usually carried out at controlled temperatures to prevent side reactions and maintain stability.

Once sodium diacetate forms in solution, crystallization is used to purify and isolate the solid product. By carefully evaporating water and adjusting temperature, sodium diacetate crystals begin to form.

In some cases, recrystallization is necessary to remove impurities, especially for food-grade or pharmaceutical use. This step improves purity and product consistency. Controlling crystallization conditions like temperature and solvent evaporation rate is vital to achieving high-quality sodium diacetate crystals.

Tip: Maintain consistent stirring and temperature control during neutralization to prevent caking and ensure uniform sodium diacetate crystal formation.

The purity of the starting materials—acetic acid and sodium salts like sodium carbonate or sodium acetate—is crucial. Impurities can affect the taste, safety, and shelf life of the final product. For food-grade sodium diacetate, reactants must meet strict purity standards, free from heavy metals, arsenic, and other contaminants. Using high-purity acetic acid and sodium salts reduces unwanted side reactions and helps achieve consistent product quality.

The reactions used to make sodium diacetate are sensitive to temperature and pressure. For example, when sodium carbonate reacts with acetic acid, carbon dioxide gas is released, increasing pressure inside the reactor. Maintaining the reaction temperature between 40°C and 50°C helps control the reaction rate and prevents the decomposition of acetic acid or the formation of undesired by-products.

High-speed stirring combined with controlled feeding of reactants ensures uniform mixing, reducing the risk of caking or uneven crystal formation. In some advanced industrial methods, reactants are sprayed into a high-pressure reactor as a fine mist, enhancing contact and reaction efficiency. Periodic venting of carbon dioxide gas prevents pressure buildup and maintains reaction stability.

Carbon dioxide is a common by-product when sodium carbonate neutralizes acetic acid. Efficient removal of this gas is essential to avoid disrupting the reaction and crystallization process. If CO₂ accumulates, it can cause foaming, uneven mixing, or pressure issues, all of which lower product yield and quality.

In industry, reactors often include venting systems to release CO₂ safely and maintain optimal pressure. Additionally, controlling the rate at which reactants are added allows the reaction to proceed smoothly without excessive gas buildup.

Sodium diacetate is widely used as a natural preservative in the food industry. Its primary role is to inhibit the growth of bacteria, molds, and yeast, which helps extend the shelf life of various food products. For example, processed meats like sausages, deli meats, and cured products benefit from sodium diacetate’s antimicrobial properties. It prevents spoilage, rancidity, and microbial contamination, ensuring food remains safe and fresh longer.

In baked goods such as bread, cakes, and pastries, sodium diacetate helps maintain freshness by reducing mold development. Snack foods like chips, crackers, and cheese-flavored products also incorporate it to improve flavor and preserve texture. Beverages, including soft drinks and fruit juices, utilize sodium diacetate as an acidity regulator, stabilizing flavor and preventing microbial growth during storage.

Regulatory agencies like the U.S. Food and Drug Administration (FDA) recognize sodium diacetate as safe, listing it under the Generally Recognized As Safe (GRAS) category. Its breakdown products—water, sodium ions, and carbon dioxide—are harmless, making it a preferred preservative in many food applications.

In chemical manufacturing, sodium diacetate acts as an intermediate or additive. It participates in various chemical reactions, especially those requiring pH adjustment or buffering. Its ability to regulate acidity makes it useful in processes where controlling the pH is critical for product stability or reaction efficiency.

Manufacturers also use sodium diacetate as a sequestering agent. It binds metal ions that could catalyze spoilage or degradation of other ingredients. This property enhances the stability of formulations in chemical products, cleaning agents, and industrial processes.

Additionally, sodium diacetate can serve as a precursor in synthesizing other chemicals. Its versatility allows it to be integrated into complex manufacturing pathways, including the production of flavor compounds or antimicrobial agents.

The pharmaceutical industry employs sodium diacetate mainly as a stabilizer and preservative in drug formulations. It helps maintain the stability and efficacy of various medicines over time. For example, it can be used in topical preparations, syrups, or injectable solutions to prevent microbial contamination.

Its antimicrobial and buffering properties ensure that pharmaceutical products remain safe during storage and use. Sodium diacetate’s safety profile—approved by regulatory agencies—makes it suitable for sensitive applications like medicines and health supplements.

In some cases, sodium diacetate is used in medical devices or wound care products to prevent bacterial growth. Its role in maintaining product integrity and safety underscores its importance across multiple sectors in healthcare.

Sodium diacetate has become an essential ingredient in various industries, especially for food preservation. This versatile compound is valued for its ability to inhibit the growth of harmful microorganisms, extending the shelf life of food products. By preventing spoilage caused by bacteria, molds, and yeast, sodium diacetate ensures that food remains fresh and safe for consumption. This is especially crucial in the production of processed meats, such as sausages, deli meats, and ready-to-eat meals, which rely on preservatives to stay fresh longer.

Beyond its preservation qualities, sodium diacetate serves as a mild flavor enhancer. Its subtle acidity provides a tangy flavor boost that improves the taste of various foods without overpowering the natural flavors. It is commonly used in baked goods, snacks, and beverages to enhance their overall taste. Additionally, sodium diacetate helps regulate the pH levels in food, ensuring that the flavor profile remains consistent during storage. This makes it particularly useful in products that are stored for extended periods, such as sauces, dressings, and canned foods.

Sodium diacetate's safety profile is another major advantage. It is recognized as safe by regulatory bodies such as the U.S. FDA and is listed under GRAS (Generally Recognized As Safe). The breakdown products of sodium diacetate—water, sodium ions, and carbon dioxide—are harmless, which makes it suitable for use in sensitive applications like pharmaceuticals and baby foods. Its chemical stability ensures that its antimicrobial and flavor-enhancing properties are maintained over time, reducing the need for constant adjustments during manufacturing and storage processes.

One of the key reasons sodium diacetate is widely used in various industries is its versatility. It can be easily incorporated into food products in various forms, such as powder, solution, or even within packaging materials. This flexibility allows manufacturers to use it in a wide range of applications, depending on the processing needs of their products. Additionally, sodium diacetate's long shelf life and stability help reduce waste and lower costs, particularly in large-scale production environments. Compared to other preservatives like benzoates or sorbates, sodium diacetate is often less restricted, making it a preferred choice for manufacturers seeking natural, clean-label solutions.

One of the biggest challenges in producing sodium diacetate is maintaining precise reaction conditions. The process involves complex chemical reactions that are highly sensitive to temperature, pressure, and reactant ratios. If these parameters are not carefully controlled, the yield and purity of the final product can suffer.

For example, during the neutralization of acetic acid with sodium carbonate or sodium hydroxide, excessive heat can cause side reactions or decomposition of the product. Too high a temperature might also lead to the loss of acetic acid through evaporation, reducing efficiency. Conversely, too low a temperature can slow down the reaction, increasing production time and costs.

Pressure control is equally important. Reactions involving sodium carbonate release carbon dioxide gas, which can build up if not properly vented. Excessive pressure may cause equipment failure or lead to inconsistent product formation. Therefore, industrial reactors must be equipped with pressure regulation systems to keep conditions within safe and optimal ranges.

Reaction time also plays a vital role. Insufficient reaction time can lead to incomplete conversion of reactants, resulting in impurities or lower yields. Overextended reaction times may cause degradation of the product or formation of unwanted by-products.

High purity of sodium diacetate is essential, especially for food and pharmaceutical applications. Impurities can originate from raw materials, incomplete reactions, or side reactions. Contaminants like heavy metals, arsenic, or residual reactants compromise product safety and effectiveness.

To ensure high purity, manufacturers must source high-quality reactants—such as acetic acid and sodium salts—that meet strict standards. Impurities in raw materials can introduce contaminants into the final product, so quality control at this stage is critical.

During production, precise control of reaction ratios and conditions minimizes the formation of impurities. For example, excess acetic acid can cause residual acidity, affecting stability. Proper filtration after the reaction removes unreacted solids and soluble impurities. Recrystallization or additional purification steps may be necessary for pharmaceutical-grade sodium diacetate.

Maintaining a clean manufacturing environment also reduces contamination risks. Equipment must be thoroughly cleaned and sanitized regularly. Analytical testing, including chromatography and spectrometry, verifies product purity before packaging.

Environmental management is a significant challenge in large-scale sodium diacetate production. The process generates by-products like carbon dioxide, which must be handled responsibly to prevent environmental harm.

Effective venting and gas treatment systems are necessary to capture and neutralize CO₂ emissions. Failing to do so can contribute to greenhouse gas accumulation, impacting climate change. Many producers implement scrubbers or absorption systems to convert CO₂ into less harmful substances or for reuse.

Wastewater management is another concern. The process may produce effluents containing residual chemicals or impurities. Proper treatment ensures that discharged water complies with environmental regulations, preventing contamination of local water sources.

Energy consumption also impacts sustainability. The process involves heating, cooling, and drying steps that consume significant energy. Optimizing these steps, such as using heat recovery systems, can reduce overall energy use.

Finally, sourcing raw materials responsibly minimizes environmental footprint. Using renewable or recycled inputs, when possible, supports sustainable manufacturing practices.

Sodium diacetate is produced through careful neutralization and crystallization processes, ensuring high purity and stability. Maintaining precise reaction conditions and managing environmental impact are crucial for quality production. Future innovations may focus on enhancing efficiency and sustainability. Yasuda offers sodium diacetate with unique benefits, providing value in food preservation and safety.

A: Sodium Diacetate is a compound made by combining sodium acetate and acetic acid, used mainly as a preservative and flavor enhancer in the food industry.

A: Sodium Diacetate is made through neutralization of acetic acid with sodium carbonate or sodium hydroxide, followed by crystallization from aqueous solutions.

A: Sodium Diacetate is used in food for its antimicrobial properties, extending shelf life and enhancing flavor.

A: Sodium Diacetate offers antimicrobial activity, flavor enhancement, safety, stability, and versatility in various industries.